https://www.google.com/intl/de/policies/privacy/

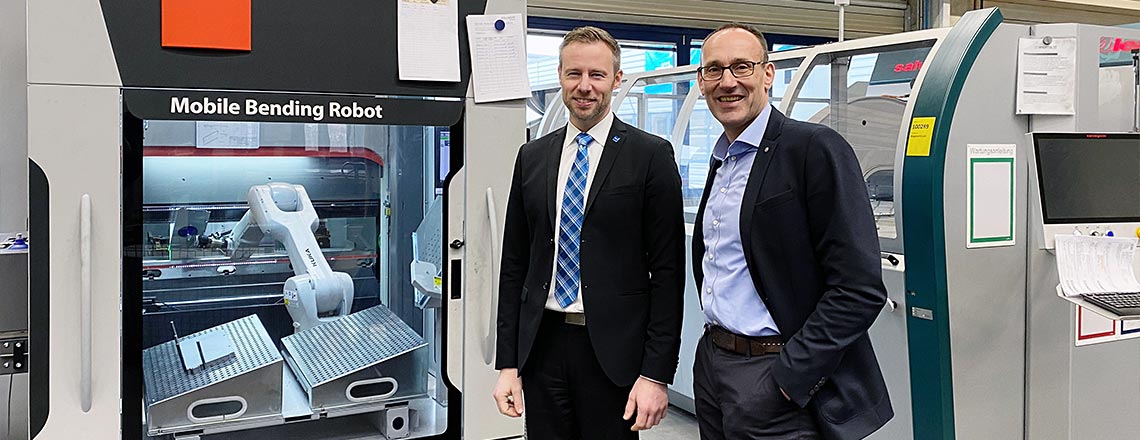

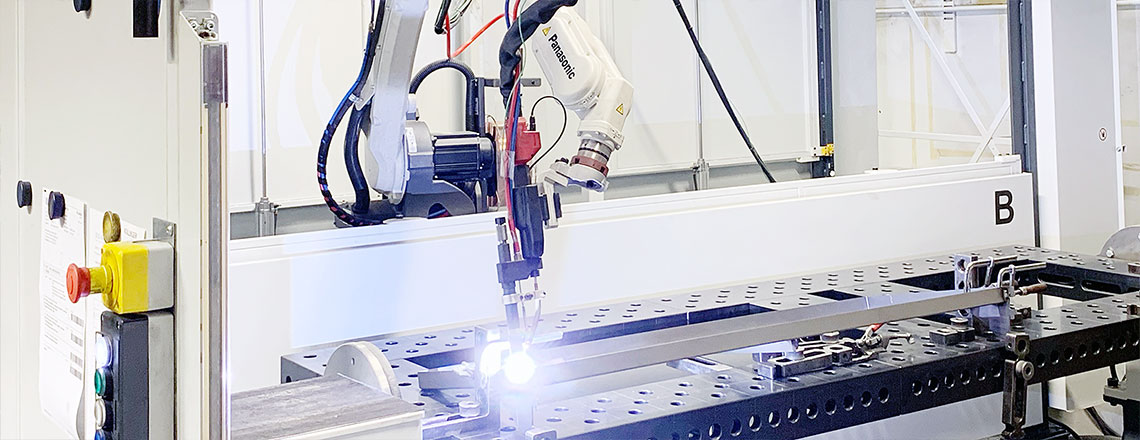

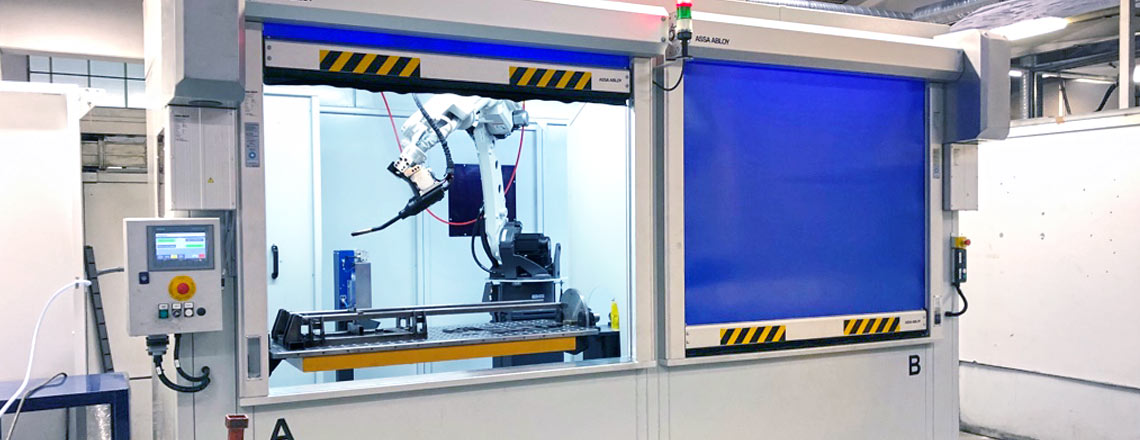

Nur die gleichzeitig wirtschaftlich und funktional beste Lösung zählt – so hat sich Kollinger einen Spitzenplatz unter den Spezialisten im Metallbau erarbeitet. Höchste Kompetenz bei der Beratung, Entwicklung und Produktion sowie Teamgeist kennzeichnen unsere 170 Mitarbeiter. Ständige Innovation und flache Hierarchien sind die Basis für unsere Flexibilität und Wettbewerbsfähigkeit.

Wir fertigen Kleinserien wie auch hohe Stückzahlen auf unserem 37.000 m² großen Gelände mit einem außergewöhnlich breit aufgestellten Maschinenpark. Seit mehr als 50 Jahren ist Kollinger dem Standort Hawangen im Unterallgäu verbunden. Heimatregion, Mitarbeiter und Kunden schätzen das Unternehmen als einen zuverlässigen und fairen Partner.

Kollinger Metallbau GmbH

Memminger Straße 17

D-87749 Hawangen

Tel. +49 (0) 83 32 / 7 90 9‑0

Fax +49 (0) 83 32 / 7 90 9‑90 00

info@kollinger.de